Through-Hole PCB Assembly Services

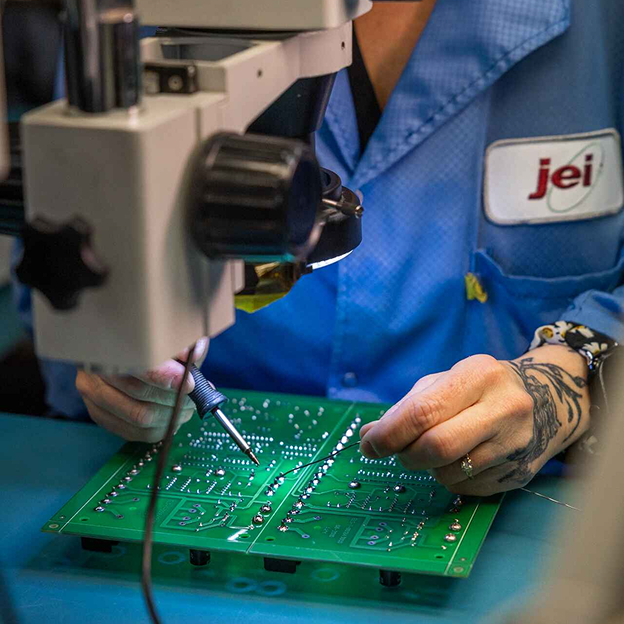

At Janco Electronics, our through-hole pcb assembly service represents decades of manufacturing excellence and precision craftsmanship. As an ISO 13485:2016 certified PCB assembly manufacturer, we deliver robust, reliable circuit board assembly solutions that meet the demanding specifications of defense, medical, RF/microwave, and industrial applications.

Proven Through-Hole Assembly Services

Through-hole technology remains essential for applications requiring superior mechanical strength, thermal performance, and long-term reliability in harsh environments. Our through-hole assembly services encompass the complete spectrum of through-hole mounting solutions, from prototype development through high-volume production runs.

Four Automated Through-Hole Processes

- Jumper Wire Insertion Our J-STD certified solderers handle critical jumper wire placement for circuit continuity, board modifications, and defect corrections. This process ensures electrical integrity between connection points while maintaining the highest quality standards.

- DIP Insertion Dual Inline Package insertion utilizes both manual and automatic machines for precise component placement. Our automated DIP insertion machines provide programmable loading and placement, while manual systems offer flexibility for specialized requirements.

- Axial Component Sequencing Pre-sequencing axial components on carrier tapes reduces assembly time and minimizes errors. This process aligns components with your PCB board assembly specifications, boosting production efficiency while reducing costly rework.

- Axial Insertion Automated axial insertion takes pre-sequenced components through precise cutting, lead forming, and insertion processes. Components transfer from sequence chains to insertion chains, where insertion heads cut leads to proper length, bend them 90 degrees, and insert them into boards with clinch assembly.

Professional Through-Hole Technology Expertise

The process of through-hole soldering demands both technical expertise and artistic precision. Our experienced soldering technicians maintain continuous certification to IPC-A-610 and J-STD-001 specifications, ensuring consistent quality throughout every through-hole pcb assembly project.

Quality-Driven Manufacturing Process

Our circuit board assembly process integrates lean manufacturing principles with rigorous quality controls. Each assembly undergoes comprehensive inspection procedures, from initial component verification through final testing protocols.

Key Capabilities:

- Manual and automated through-hole insertion

- Wave soldering and selective soldering

- Mixed technology board assembly

- Component lead forming and trimming

- Post-solder inspection and testing

- Rework and repair services

Industries We Serve

Our through-hole assembly services support critical applications across multiple sectors:

- Defense & Aerospace Through-hole components provide the mechanical durability required for harsh environmental conditions in military applications.

- Medical Devices ISO 13485 certification ensures our medical device assemblies meet stringent regulatory requirements for Class II and Class III devices.

- RF/Microwave Specialized expertise in high-frequency applications where through-hole technology offers superior electrical performance.

- Industrial & Commercial Robust assemblies designed for long-term reliability in demanding industrial environments.

Advanced Manufacturing Capabilities

As a premier PCB assembly manufacturer, Janco Electronics combines traditional through-hole expertise with modern manufacturing technologies:

- Automated insertion equipment for high-volume efficiency

- Wave soldering systems for consistent joint quality

- Selective soldering for complex mixed-technology boards

- X-ray inspection for internal joint verification

- Flying probe testing for comprehensive electrical validation

Partner with American Manufacturing Excellence

Located in Rollinsford, New Hampshire, Janco Electronics delivers the personal attention and quality focus that distinguishes American manufacturing. Our 60+ years of experience, combined with ISO certification and robust quality management systems, ensures your through-hole pcb assembly meets the highest industry standards.

Every project receives dedicated engineering support, from design for manufacturability consultation through final delivery. Our team works closely with customers to optimize assembly processes, reduce costs, and accelerate time-to-market while maintaining uncompromising quality standards.

Quality Management System

Our comprehensive quality management system encompasses:

- Incoming component inspection with counterfeit mitigation protocols

- Process control documentation for every assembly step

- Statistical process control monitoring critical parameters

- Final inspection and testing before shipment

- Continuous improvement programs driving operational excellence

Ready to partner with a proven through-hole PCB assembly service provider? Contact Janco Electronics to discuss your specific requirements. Our engineering team stands ready to deliver the precision, quality, and reliability your projects demand.