Facility & Equipment

State-of-the-Art Manufacturing Excellence

Located in Rollinsford, New Hampshire, our modern manufacturing facility houses advanced equipment operated by certified technicians committed to delivering precision electronics manufacturing. Built around efficient workflow and lean manufacturing principles, our facility combines decades of experience with cutting-edge technology to serve defense, medical, commercial, and RF/microwave markets. Every piece of equipment in our facility operates under our ISO 13485:2016 certified Quality Management System, ensuring consistent, high-quality results for our manufacturing partners.

Surface Mount Technology (SMT)

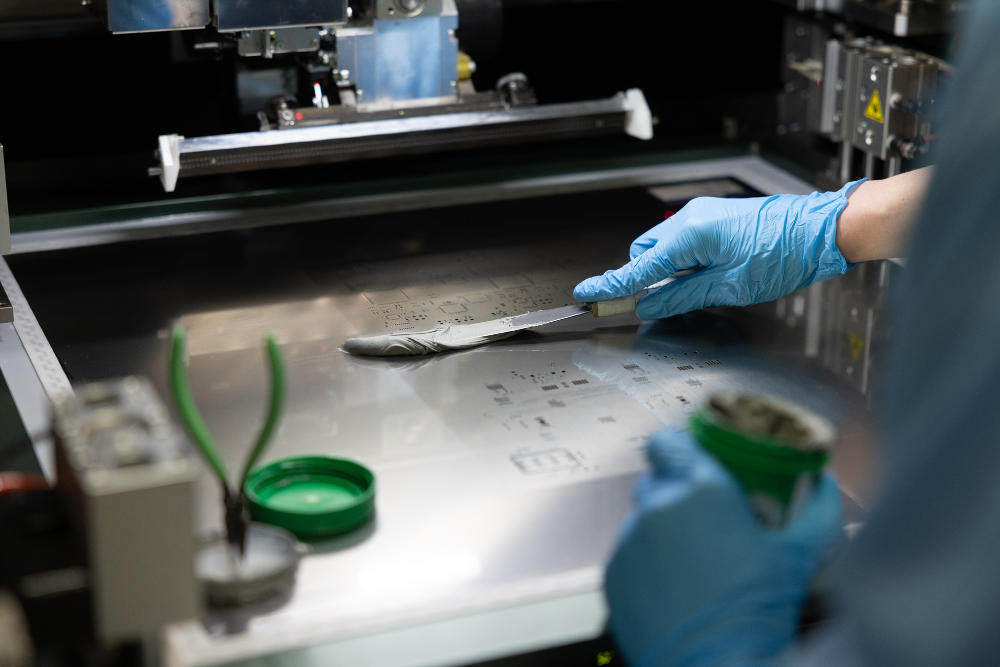

Solder Paste Stencil Printer

Precision automated stencil printing systems for accurate solder paste deposition across all pad geometries and component types.

Solder Paste Inspection (SPI)

Automated inspection systems measuring paste volume, height, and placement accuracy before component placement, ensuring optimal solder joint formation.

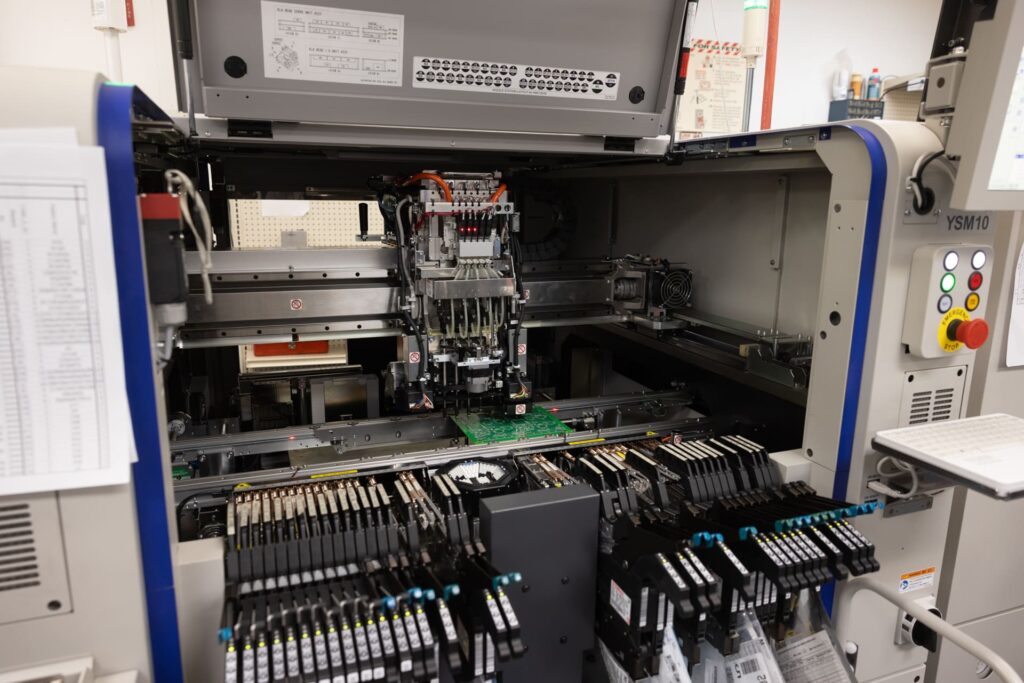

Pick & Place Equipment

High-speed automated placement systems for precise component positioning, supporting components from 0201 chip components to large BGAs.

Reflow Profiling

Advanced reflow ovens with multi-zone temperature control and real-time profiling capabilities for both leaded and RoHS-compliant lead-free processes.

Learn more about our Surface Mount Assembly Services

Through-Hole & Mixed Technology Assembly

Wave Solder Systems

Dual-capability wave soldering equipment supporting both leaded and RoHS lead-free processes for high-volume through-hole component assembly.

Selective Solder Equipment

Programmable selective soldering systems for mixed-technology boards, providing targeted solder application for through-hole components without thermal stress to SMT assemblies.

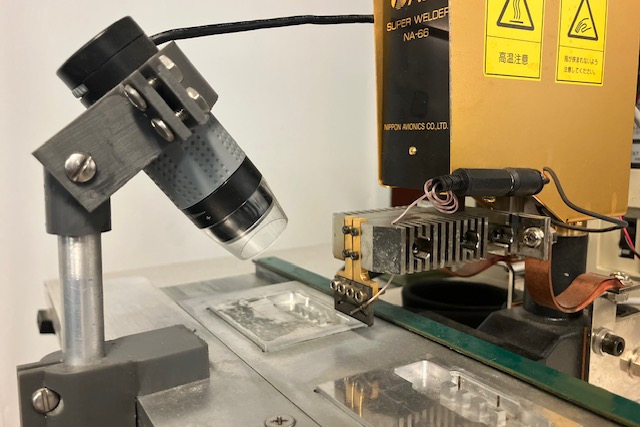

Hot Bar Solder Equipment

Precision thermode soldering systems for specialized applications including flex circuit attachment, connector assembly, and heat-sensitive component installation.

Explore our Through Hole PCB Assembly capabilities

Cleaning & Processing

Aqueous Wash Systems

Automated cleaning equipment using water-based chemistries for flux residue removal and ionic contamination cleaning, ensuring assembly cleanliness for critical applications.

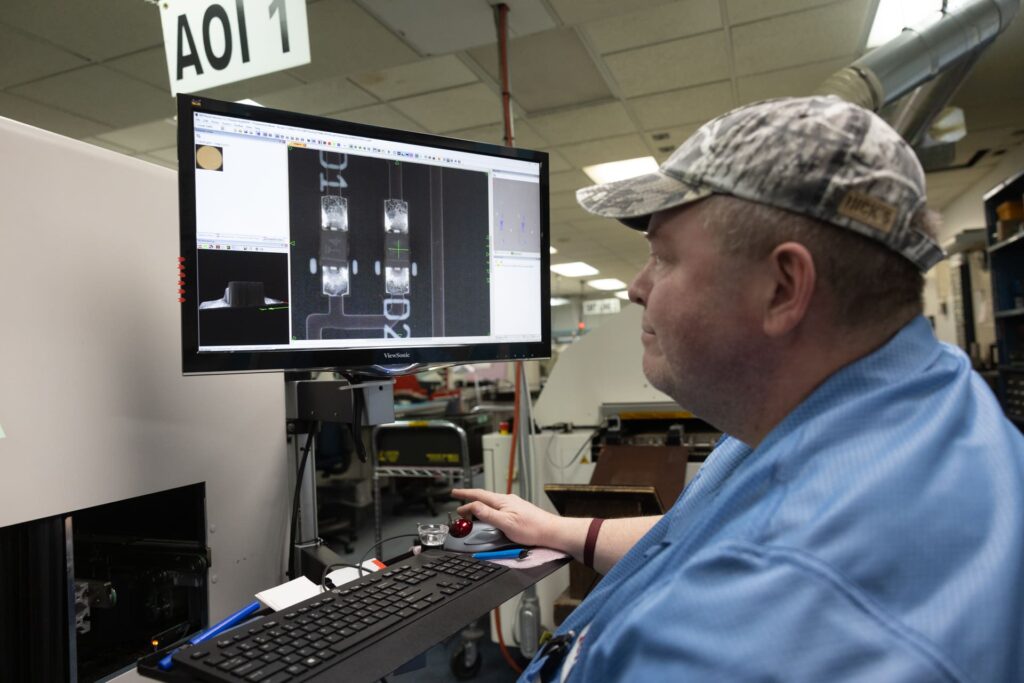

Inspection & Quality Assurance

- Automated Optical Inspection (AOI) High-resolution post-reflow inspection systems for comprehensive solder joint quality verification, component presence, and placement accuracy assessment.

- X-Ray Inspection Advanced 2D X-ray systems for non-destructive inspection of hidden solder joints, BGA void analysis, and internal assembly verification.

Discover our comprehensive Quality Standards

RF & Microwave Test Equipment

Network Analyzers & Signal Generators

Precision RF measurement equipment for S-parameter characterization, frequency response analysis, and comprehensive RF performance verification.

Environmental Test Chambers

Temperature and humidity cycling chambers for environmental stress testing and qualification of electronic assemblies.

Learn about our specialized Electronics Testing services

Partner with Proven Excellence

Our advanced equipment, combined with over 60 years of manufacturing expertise and ISO 13485:2016 certification, ensures your electronic assemblies meet the highest quality standards. From prototype to production, our facility is equipped to handle your most demanding manufacturing requirements.

Ready to discuss your project? Contact our engineering team to learn how our equipment capabilities can support your next electronics manufacturing challenge.

Ready to ensure your assemblies meet the highest quality standards? Contact our testing experts today to discuss your specific requirements and learn how our proven testing capabilities can support your manufacturing objectives.