As am OEM, if the idea of systems failures and downtimes, safety hazards, and reduced performance and lifespan gives you pause, then it’s time to develop and implement a Counterfeit Parts Mitigation Policy that encompasses your company and any of your manufacturing partners. A Counterfeit Part is “defined as a ‘fraudulent part’ that has been confirmed to be a copy, imitation, or substitute that has been represented, identified, or marked as genuine, and/or altered by a source without legal right with the intent to mislead, deceive, or defraud.” 1 Counterfeit goods can cause a significant risk to the supply chain, and depending on the industry, could potentially result in a loss of material, mission, or life.

According to ERAI, a global organization that monitors and reports issues affecting the electronics supply chain, the most counterfeited electronic components are Analog ICs, Programmable Logic ICs, and Microprocessor ICs. Together, in 2023, they accounted for nearly half of all reported counterfeit components. In 2023, counterfeiters targeted obsolete parts the most (45.7%), and active, long lead time parts were not far behind at 32.8%. 2 Given that even active parts are not immune to counterfeiting, the ERAI strongly urges companies to perform all recommended levels of testing on all parts purchased anywhere other than the actual manufacturer or the manufacturer’s authorized distributor that offers full traceability.

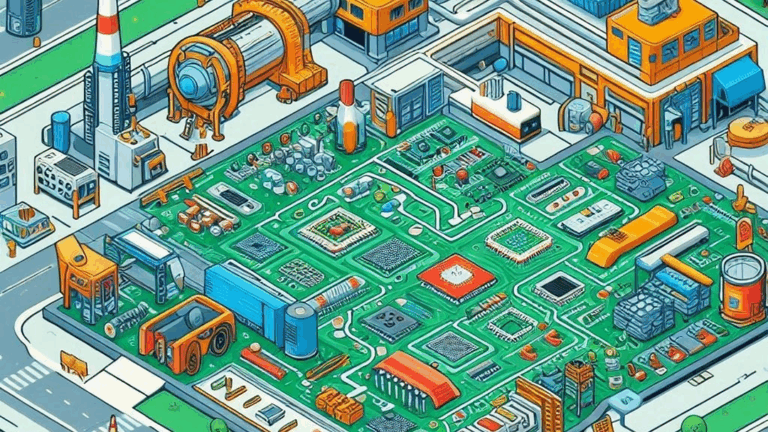

We know that as technology advances, so does criminal activity. Electronic components are no exception. Electronic component counterfeiters use several methods to deceive the industry, but we’ll look at the three most common:

“Component Bare Piece” Method– counterfeiters purchase bare die components (small pieces of integrated circuits without packaging), seal and test them, then sell them as their own product or under a more well-known brand.

“Label Switching” Technique– This is one of the most deceptive practices. Counterfeiters source similar materials from other brands and swap out the original labels for those of a higher value, targeted component. The counterfeit part may look almost identical to the genuine one, but its quality and performance is far below.

“Weak for Strong” Method– similar to “Label Switching,” counterfeiters take lower grade components and relabel them as higher quality components. For example, a component rated for a certain operating temperature may be relabeled as a higher grade, hotter operating temperature. Another example would be relabeling a 5% tolerance part as a 1% tolerance, making the buyer believe they’re purchasing a far superior part.

A comprehensive counterfeit mitigation policy involves preventative action at both the buying stage and the receiving stage. It’s important to understand the ways in which counterfeiters slip their fraudulent parts into the supply chain and the ways to identify them. Here are the top six things to look for when inspecting all incoming components:

Incorrect Information – counterfeit manufacturers in China lack the ability to replicate markings on the part packaging. For example, look for incorrect fonts, misspelled words, incorrect part numbers, logo, or country of origin.

Resurfacing – also known as “blacktopping,” resurfacing is achieved by sanding off the original markings of the component and applying a new coat of polymer to cover them up. This often leaves visible clues. For example, indents on a chip that has been blacktopped will be partially filled with polymer or the smoothness of the indent’s original surface will still be visible.

Physical Deformities – any physical abnormalities should tip you off to possible authenticity issues with components. We know that counterfeit parts are sometimes pieced together from scrap electronics and sold off as being “new.” If this is the case, typically, some wear and tear will be visible.

There are times when the additional use of tools is needed to identify counterfeit components:

X-ray Inspection – X-ray inspection can identify irregularities of the internal contents of the part. Some indicators to look for are missing or inconsistent die sizes, visible delamination, and broken or missing wire bonds. If the part is RoHs approved, X-ray inspection can be used to confirm its lead-free status, which is something many counterfeiters overlook.

Scanning Acoustic Microphone (SAM) – a Scanning Acoustic Microphone is used to locate laser etching under blacktopping. If etching is present, it’s likely that resurfacing was used to cover up original markings. Use of a SAM is non-destructive, so if the component passes inspection, it can still be used.

Destructive Testing – unlike using the SAM, Destructive Testing methods destroy the component, so it is useless regardless. One method is called “Decapsulation,” in which a tester places abrasive acids on the surface of the component until the internal die reveals itself. The die is, in turn, inspected by microscope.

While these are all good methods to identify potentially counterfeit components, if you want to mitigate the risk of receiving counterfeits, your company’s Counterfeit Parts Control Plan should take a proactive approach and address procurement methods as well. You should limit your purchases to authorized distributors and consistently run tests on your incoming components. Of course, if your team needs to find obsolete or hard-to-find parts, you may have to look at sources outside your authorized distributors. In these cases, you should partner with your customer and get their approval before doing so. Once those parts come in, follow procedures outlined in your company’s Counterfeit Parts Control Plan.

If you’re vetting potential electronics manufacturing partners, make sure every one of them has a robust Quality Management System that includes a proactive Counterfeit Parts Mitigation Plan. At Janco Electronics, we understand that parts procurement is critical for the quality and safety of the electronic assemblies we build for our customers. We don’t just evaluate the parts; we take corrective actions to stop counterfeiters in their tracks by removing any suspected counterfeits from our supply chain and reporting them to the appropriate agency. When it comes to building the best quality assemblies and delivering them to our customers on time, there are no tolerances.