Electromechanical Contract Manufacturing Services

Comprehensive Electromechanical Assembly Services

Our electromechanical assembly services encompass the complete integration of electronic and mechanical components into robust, reliable systems. From initial PCB assembly through final system integration and testing, we provide turnkey solutions that meet stringent industry specifications.

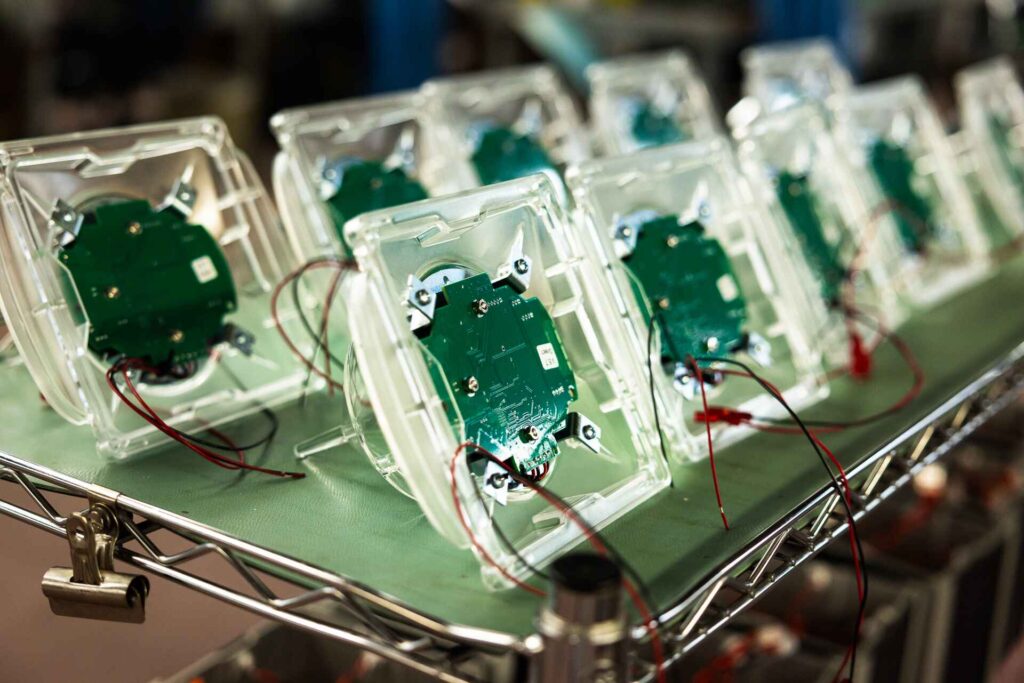

PCB Box Build Assembly Services

- Enclosure Integration: Precision mounting of PCB assemblies within custom or standard enclosures

- Component Integration: Installation of displays, switches, connectors, and user interface elements

- Thermal Management: Heat sink installation and thermal interface material application

- Environmental Protection Measures: Conformal coating, epoxy potting, and other customer driven requirements

- Functional Testing: Replicate customer functional bench test requirements

Advanced Box Build Assembly Services

Our box build assembly services extend beyond basic enclosure work to include complete system-level integration. We handle complex multi-board assemblies, power supply integration, and sophisticated interconnect systems that demand precision manufacturing and rigorous quality control.

Electromechanical Box Builds for Critical Applications

Defense and Aerospace Systems

Our electromechanical systems contract manufacturing supports defense contractors with:

- ITAR-registered facility and processes

- ISO-certified quality management system capabilities

- Environmental testing and qualification

- Full traceability and documentation

Medical Device Integration

As an ISO 13485:2016 certified medical device manufacturer, we provide:

- Class I and II medical device assembly

- FDA compliance and documentation

- Clean environment assembly capabilities

Electromechanical Assembly Expertise

Our electromechanical assembly process begins with your populated circuit boards and extends through complete system integration. We leverage decades of experience in both electronic assembly and precision mechanical work to deliver systems that perform reliably in demanding environments.

Value-Added Manufacturing Services

- Design for Manufacturability (DFM): Early-stage consultation on New Product Introduction to optimize designs for efficient assembly

- Supply Chain Management: Comprehensive component sourcing and inventory management

- Environmental Testing: Thermal cycling, vibration, and environmental stress screening

- Functional Testing: Comprehensive system validation

Quality Management System Excellence

- ISO 13485:2016 Medical Device Certification

- IPC-A-610 Acceptability Standards

- J-STD-001 Soldering Requirements

- Continuous improvement processes

- Statistical process control

Advanced Manufacturing Capabilities

Precision Assembly Technologies

- Surface Mount Technology (SMT) with fine-pitch BGA capability

- Through-hole component insertion and soldering

- Mixed-technology board assembly

- Flexible circuit integration

- Conformal coating application

Testing and Validation

- Flying probe and in-circuit testing

- Functional test capabilities

- RF and microwave testing capabilities

- Environmental stress screening

- Thermal chamber testing

Turnkey Electromechanical Contract Manufacturer

Project Management Excellence

- Dedicated project management for complex assemblies

- Real-time production status reporting

- Quality milestone tracking

- On-time delivery performance

Supply Chain Partnership

- Authorized distributor relationships

- Counterfeit parts mitigation program

- Component obsolescence management

- Flexible inventory programs including consigned and bonded stock

Industry-Leading Documentation Standards

- Bill of Materials (BOM) with manufacturer specifications

- Assembly drawings detailing unique requirements

- PCB fabrication drawing with dimensional, material, and other requirements

- Gerber and drill files

- Design database CAD; ASCII PADS ODB++ Outputs

- Test procedures and acceptance criteria

- Work instructions and quality checkpoints

Partner with Janco Electronics

Choose Janco Electronics as your electromechanical assembly service provider and benefit from our people-first philosophy, where our experienced team applies decades of manufacturing expertise to deliver exceptional results. Our commitment to quality, combined with American manufacturing excellence, ensures your critical systems perform reliably in the field.

Contact our engineering team today to discuss your electromechanical contract manufacturing requirements. Let us demonstrate how our expertise, quality management system, and customer-focused approach can support your next project.

Ready to partner with an experienced electromechanical contract manufacturer?