Understanding BGA Rework — A Cornerstone of Modern Electronics Manufacturing

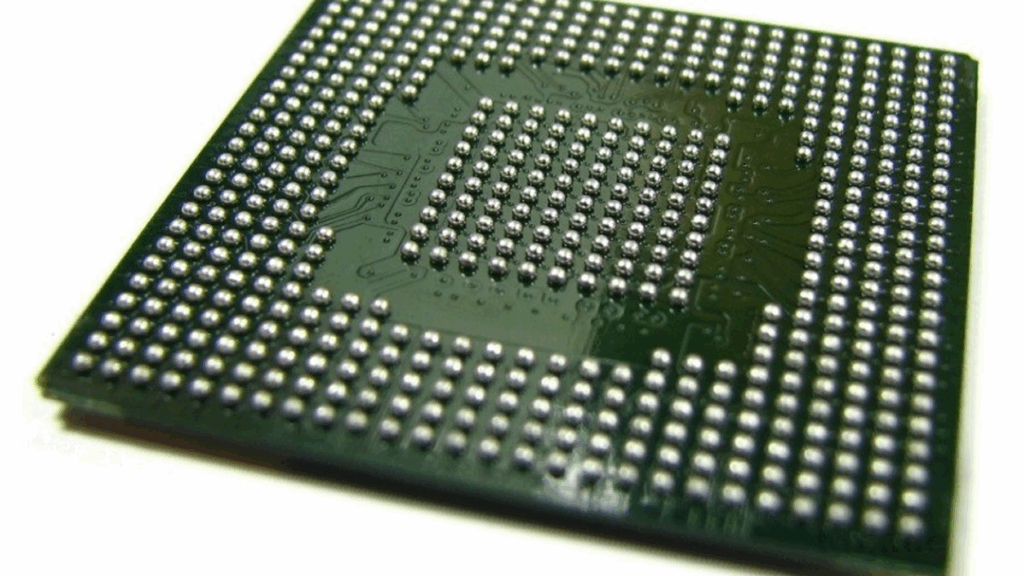

In today’s tech-driven world, electronics are getting smaller, faster, and more complex—at the heart of many of these devices lies a critical component: the Ball Grid Array (BGA). While powerful in performance, BGAs are notoriously difficult to handle when things go wrong. This is where BGA rework steps in as a vital service within Electronics Manufacturing Services (EMS). Let’s explore why mastering the fundamentals of BGA rework isn’t just helpful—it’s essential.

What is BGA Rework?

BGA rework is the process of removing, repairing, or replacing a BGA component on a printed circuit board (PCB). Unlike traditional components with visible pins, BGAs have solder balls beneath them, hidden from view. This invisible architecture creates a compact design but poses challenges for inspection and repair.

The Rework Process – Step-by-Step

– Preparation: The PCB is carefully cleaned and prepped. Flux is applied to minimize oxidation and improve solder flow.

– Removal: A precision rework station heats the board to lift the BGA without damaging underlying pads.

– Pad Cleaning: Solder residue is wicked away, and the surface is cleaned using solvents like isopropyl alcohol.

– Reballing (if needed): If the original BGA is reused, fresh solder balls are added via a stencil and heat process.

– Replacement: A new or reballed BGA is aligned on the PCB, and solder paste is applied.

– Reflow: Controlled thermal profiling melts the solder, securing the BGA in place.

– Inspection: X-ray or specialized optical systems verify the integrity of solder joints hidden beneath the BGA.

Why Is BGA Rework Crucial for EMS?

- Cost Efficiency: Reworking a defective or misaligned BGA is often far cheaper than scrapping an entire PCB, especially for expensive, high-density boards.

- Quality Assurance: Offering BGA rework ensures EMS providers can meet high standards without delays or outsourcing to third-party specialists.

- Environmental Impact: Repairing instead of replacing cuts down on electronic waste—a growing global concern.

- Flexibility in Prototyping and Customization: During R&D, components often need swapping to test variants. BGA rework enables rapid iterations without full re-manufacture.

- Reduced Downtime:In industries like aerospace, medical tech, and telecommunications, faulty boards must be fixed fast—having on-site BGA expertise minimizes disruption.

The Tools Behind the Magic

Successful BGA rework requires high-precision tools:

-Top-and-bottom heated rework stations

-Solder paste printers and flux

-Stencils and reballing kits

-X-ray machines for hidden joint inspection

-Microscopes and tweezers for delicate adjustments

Final Thoughts

In the ever-evolving landscape of electronics, the ability to rework BGA components is not just a technical skill—it’s a strategic advantage. At Janco Electronics Inc., we offer robust BGA rework services distinguishing ourselves as adaptive, efficient, and quality-focused partners in a fast-paced industry.